Conductor paths integrated into textiles enable new functions, micro-electronics become a fashionable accessory and offer endless perspectives of wearable applications in the field of e-health. In order to make previously analog textiles and devices smart, innovative and sustainable ideas as well as implementation variants for the fashion sector from textiles and technology must be developed.

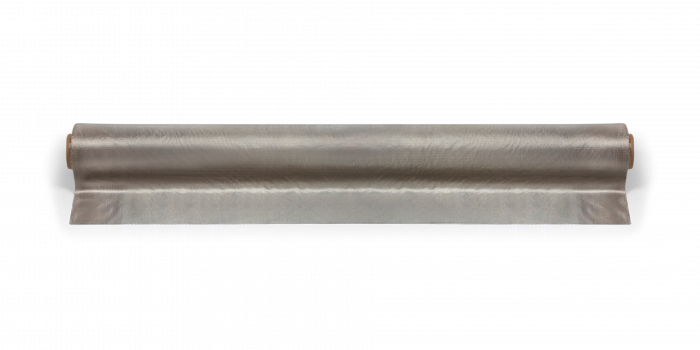

With Shieldex, user-oriented rehabilitation garments can be developed that enable patients, for example after a stroke, to train their bodies under supervision. Sensors produced from the conductive Shieldex yarn by textile sensor manufacturers can measure muscle activity and thereby optimize the rehabilitation process. The training data sent to a processing module can be evaluated via an app, for example, and thus provide helpful information about the healing process.